SaskPower has long said that the next generation of carbon capture on its coal-fired power plants would cost a lot less, and now we have a number – 67 per cent less, per tonne of CO2 captured.

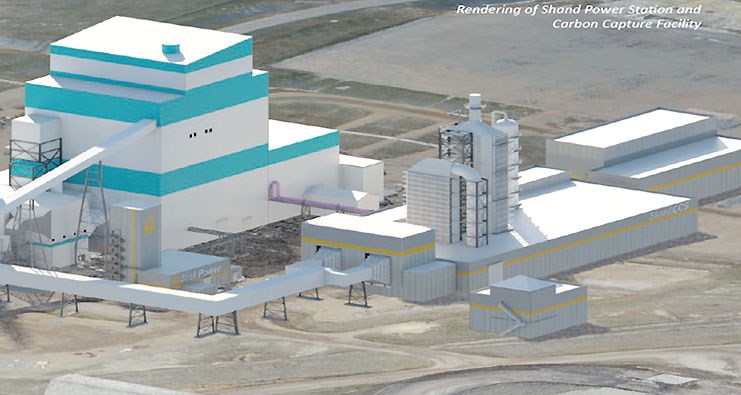

That’s the key the message from the feasibility study to retrofit SaskPower’s Shand Power Station, a 300-megawatt, single unit, coal-fired power plant with a large-scale carbon capture facility that has double the capacity of Boundary Dam Unit 3 (BD3) CCS Facility. The Shand facility would be designed to capture two million tonnes of CO2 per year, and would include a sulphur dioxide (SO2) abatement.

The study was released at a conference in Edinburg, Scotland, on Nov. 28 by the Regina-based and SaskPower-affiliated International CCS Knowledge Centre.

Corwyn Bruce, head of technical services and lead author of the study, spoke to media back in Saskatchewan via a conference call.

He opened by noting that BD3 had pioneered the way for CCS around the world, and said the Intergovernmental Panel on Climate Change has found that almost every pathway which leads to limiting global warming to 1.5 C includes carbon capture and storage.

Shand was considered because it is an open site with lots of room for a carbon capture facility, and it is the newest in SaskPower’s fleet of coal-fired power generating units (excluding BD3). Also, the turbine designs are very similar to that of BD6 and Poplar River Units 1 and 2, so there could be similar results expected if those facilities were used. Shand also already has a Carbon Capture Test Facility, which can be used for piloting.

As for the 67 per cent cost reduction, per tonne, he pointed out that Shand, at 300 megawatts, would be twice the size of Boundary Dam, and there are “benefits of scale.” This includes a much shorter construction schedule.

Bruce said there were many redundancies and “extra parts” included in BD3. “Some of those features are no longer required,” he said of a second generation capture plant.

The BD3 project came in at roughly half a billion dollars for the retrofit of the power station, and a further billion dollars for the carbon capture plant. Since Shand is so much newer, its retrofit would be much less costly – less than $100 million, Bruce said. On a per-megawatt basis, there would be a 92 per cent reduction in cost, as Shand’s generator is twice as big.

Much of the retrofit cost would be within the turbine itself, changing blades, for instance, whereas BD3 was largely rebuilt and had a brand new, specially-built turbine.

Due to local lignite coal being high in fly ash and wet, two things that used to be considered negatives, are now considered advantages. The water, which currently goes up the smokestack as steam, would condense in the carbon capture facility and could be used for cooling, meaning there would not be a need for additional water to be drawn into the plant. He noted this would be quite useful in other locations in the future, as thermal facilities are often limited by how much water they can draw.

As for the fly ash, which is used as a component of cement, there’s an offsetting benefit, too. “Every tonne of fly ash reduces CO2 by 0.9 tonnes in cement making,” he said.

The carbon capture unit would be designed to capture 90 per cent of the CO2 emissions from 100 per cent of the flue gas. When the offset from fly ash used in cement is included, Bruce explained the effective greenhouse gas emissions of the facility would be zero.

As renewable energy is added to the grid, thermal plants reduce their output to make room for that renewable power on the grid. But that results in them being less efficient, overall. Bruce explained that, with regards to CO2 capture, a 62 per cent electrical load would result in capturing 97 per cent of the CO2 produced.

As for the total cost of the carbon capture facility, Bruce said it would be in the range of a billion dollars. While that is close to what BD3’s carbon capture plant cost, this would have double the capacity.

With regards to what happens with the carbon dioxide once captured, Bruce alluded to integrating it with the carbon dioxide being captured at BD3, creating a CCS hub. That would mean more than one capture plant tied into a common system. However, he did not speak of where exactly the CO2 would be used. His implication was that, like Boundary Dam 3’s carbon dioxide, it would be used in enhanced oil recovery.

Bruce said, "There is within a reasonable distance of Shand, the capacity to store 230 million tonnes of CO2, potentially unlocking up to 660 Million barrels of oil, and of course there are other benefits of potentially tying two CCS plants together in order to provide a more consistent and reliable supply of CO2.

In related news, SaskPower president and CEO Mike Marsh is scheduled to speak to the Estevan Chamber of Commerce at a luncheon on Dec. 6.